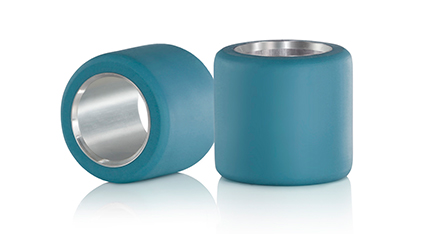

A. JKS ALUPRESS COTS

Swipe to see full tables on mobile devices

Swipe to see full tables on mobile devices| Name | Shore Hardness[°A] |

color | application | characteristics | Fibres | Fibres | Fibres | Fibres | Fibres | Fibres |

|---|---|---|---|---|---|---|---|---|---|---|

| JKS-CN-630 | 63 | apricot | Front Roller | Spinning Process: • ring spinning: 60 days grinding cyle* • compact spinning: 30-45 days grinding cycle* | 100% cotton super fine count | |||||

| JKS-CN-650 | 65 | pine | Front Roller | Spinning Process: • ring spinning: 60-90 days grinding cyle* • compact spinning: 45 days grinding cycle* | 100% cotton fine count | |||||

| JKS-CN-660 | 66 | honey | Front Roller | Spinning Process: • ring spinning: 60-90 days grinding cyle* • compact spinning: 45 days grinding cycle* | 100% cotton medium to fine count | cotton/ blends fine count | ||||

| JKS-CN-680 | 68 | sky, plum | Front Roller | Spinning Process: • ring spinning: 90-140 days grinding cycle* • compact spinning:45-60 days grinding cyle* | cotton | cotton/ blends | TC | viscose | CV | |

| JKS-CN-700 | 70 | orange, moon | Front Roller | Spinning Process: • ring spinning: 100-150 days grinding cycle* • good conductor of electrical charges • superior fibres control | cotton | cotton/ blends | TC | viscose | wool | silk |

| JKS-CN-730 | 73 | mint | Front Roller | Spinning Process: • special development for compact spinning • excellent fibres control in improved U% • lapping resistance | cotton/ blends | TC | viscose | wool | coarse to fine counts | |

| JKS-CN-750 | 75 | apple | • Front & Back Roller • Back Roller for 100% cotton | Spinning Process: • excellent fibres control in improved U% • excellent grooving resistance | polyester/ cotton | synthetics | ||||

| JKS-CN-800 | 80 | carbon | • No Front Roller application • Middle Roller | Spinning Process: • ring spinning | 100% acrylic | 100% synthetic | 100% polyester | coarse count | ||

| JKS-CN-830 | 83 | stone, chili | Front & Back Roller | Spinning Process: • ring spinning • universal trouble free cot • good conductor of electrical charges • resistant to flute marks | all fibres | wool | ||||

| JKS-CN-850 | 85 | sapphire | Front & Back Roller | Spinning Process: • ring spinning • antistatic, antifusion • abrasian resistance • lapping resistance | 100% synthetic | 100% acrylic | 100% polyester | coarse count | ||

| JKS-CN-900 | 90 | sand | Front & Back Roller | 100% harsh fibres |

Grinding cycle depending on count and working condition.

JKS ALUPRESS COTS – JKS DURA COTS

| Name | Shore Hardness[°A] |

color | characteristics | Fibres | Fibres | Fibres | Fibres | Fibres |

|---|---|---|---|---|---|---|---|---|

| JKS-CD-630 | 63 | apricot | • front roller • ring spinning: 60 days grinding cyle* • compact spinning: 30-45 days grinding cycle* | 100% cotton super fine count | ||||

| JKS-CD-660 | 65 | honey | • front roller • ring spinning: 60-90 days grinding cyle* • compact spinning: 45 days grinding cycle | 100% cotton medium to fine count | cotton/ blends fine count | |||

| JKS-CD-680 | 66 | sky | • front roller • ring spinning: 90-140 days grinding cycle* • compact spinning: 45-60 days grinding cyle* | cotton | cotton/ blends | TC | viscose | CV |

| JKS-CD-700 | 70 | moon | • front roller • ring spinning: 100-150 days grinding cycle* • good conductor of electrical charges • superior fibres control | cotton | cotton/ blends | TC | wool | silk |

B. JKS RUBBER APRONS

| Name | color | application | characteristics | Fibres | Fibres | Fibres | Fibres | Fibres |

|---|---|---|---|---|---|---|---|---|

| JKS-AR* -110 | olive | Top & Bottom Apron | Spinning Process: • finish electrolytic • excellent ozone resistance of outer layer • soft inner layer causes higher supple | 100% cotton medium to fine count | ||||

| JKS-AR* -111 | kiwi | Top & Bottom Apron | Spinning Process: • special rubber compound/upgrade of JKS AR 110 • high performance an compact applications • excellent U% results • improved life time • as short bottom apron – recommended for all fibres | 100% cotton fine count | cotton / blends fine count | |||

| JKS-AR* -511 | sun | Top & Bottom Apron | Spinning Process: • special rubber outer layer for compact spinning • special Suessen EliTe compact development • excellent spinning performance | 100% cotton coarse count | low traverse | zero traverse | ||

| JKS-AR* -570 | petrol | Top & Bottom Apron | Spinning Process: • special development for application wool/blends | wool | wool / blends | poly wool | ||

| JKS-AR* -684 | berry | Top & Bottom Apron | Spinning Process: • ring spinning frames • finish electrolytic • soft and flexible innerlayer causes smooth rotation | 100% cotton low to medium coun | cotton / blends | wool | lycra | |

| JKS-AR* -750 | lotus | Top & Bottom Apron | Spinning Process: • ring spinning frames and roving frames • soft and flexible innerlayer causes smooth rotation • special rubber compound | all fibres | ||||

| JKS-AR* -909 | jade | Top & Bottom Apron | Spinning Process: • special wear and tear resistance for harsh fibers | 100% synthetic | 100% cotton coarse coun | dyed yarn | silk | |

| JKS-AR* -930 | ocean | Top & Bottom Apron | Spinning Process: • special raw material with antistatic, antioxidant agents | 100% synthetic harsh fibres and acrylic | kevlar | PPE | polyester / viscose |

*

ARPE = Apron Rubber plain endless ARPS = Apron Rubber plain open skived

ARKE = Apron Rubber knurled endless ARKS = Apron Rubber knurled open skived

ARPE = Apron Rubber plain endless ARPS = Apron Rubber plain open skived

ARKE = Apron Rubber knurled endless ARKS = Apron Rubber knurled open skived

C. JKS PRODUCTS – AIR-JET-SPINNING

| Name | Shore Hardness[°A] |

color | application | Fibres | Fibres | Fibres |

|---|---|---|---|---|---|---|

| JKS-CR-800 | 80 | azure | • High speed spinning mc/s • MVS & MJS mc/s • Rieter Air Jet mc/s • Saurer Autoairo mc/s |

100% viscose | fine count | available in “normal” and recessed execution |

| JKS-CR-850 | 85 | hazel | all fibres | available in “normal” and recessed execution |

D. JKS PRODUCTS – COMPACT SPINNING

| Name | Shore Hardness[°A] |

color | application | characteristics |

|---|---|---|---|---|

| JKS-ARPE-684 | berry | Top Apron | Spinning Process: • Compact mc/s • perforation: slot, hole, hole for coarse to medium count • perforation: hole, hole, hole for fine count • perforation: in and off-centre • perforation: in one or two rows for wool |

Grinding cycle depending on count and working condition.

E. JKS PRODUCTS – TEXTURISING

| Name | Shore Hardness[°A] |

color | application | characteristics |

|---|---|---|---|---|

| JKS-ART-330 | cherry | Apron | • for high speed Barmag mc/s | |

| JKS-ART-247 | caramel | Apron | • for Heberlein, ARCT and Murata mc/s up to 1.200 m/min • Barmag mc/s | |

| JKS-CT-600 | 63 | coral | Cot | • available in Alupress, Springrip and plain construction • for Giudici, Scragg and ICBT mc/s • for fine fibres |

| JKS-CT-650 | 67 | nougat | Cot | • available in Alupress, Springrip and plain construction • for high speed mc/s |

| JKS-CT-700 | 73 | peach | Cot | • available in Alupress and Springrip construction • for harsh fibres |

F. JKS PRODUCTS – PRE-SPINNING

JKS Alu Cots for Draw Frame mc/s

| Shore Hardness[°A] |

color | application | characteristics |

|---|---|---|---|

| 65* | pine | Alupress Cot | • plain and spirally grooved • no adhesive is required • no stress on the cots • no cot slippage |

| 70* | moon | Alupress cot | |

| 75* | apple | Alupress cot | |

| 80* | carbon | Alupress Cot | |

| 83* | stone | Alupress Cot | |

| 85* | sapphire | Alupress Cot | |

| 90* | sand | Alupress Cot |

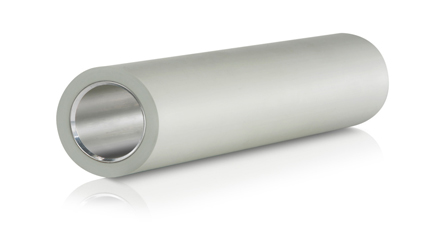

JKS Springrip Cots for Draw Frame mc/s

| Shore Hardness[°A] |

color | application | characteristics |

|---|---|---|---|

| 65* | pine | Springrip Cot | • plain and spirally grooved • no adhesive is required – only as lubricant • no stress on the cots • price advantage |

| 70* | moon | Springrip Cot | |

| 75* | apple | Springrip Cot | |

| 80* | carbon | Springrip Cot | |

| 83* | stone | Springrip Cot | |

| 85* | sapphire | Springrip Cot | |

| 90* | sand | Springrip Cot |

JKS Dura Cots for Comber mc/s

| Shore Hardness[°A] |

color | application | characteristics |

|---|---|---|---|

| 65 | salmon | Dura Alupress Cot | • very soft plus area Inside – Share Hardness 50°A • excellent fibres handling • high performance product • improved hairiness results in spinning process |

G. JKS Leather Apron

| Name | color | application | characteristics | Fibres | Fibres |

|---|---|---|---|---|---|

| JKS-AL* -033 | arctic | Bottom Apron | • endless making with extraordinary ,lip and stick’ system like a stamp • perfect handling features as repair apron | 100% cotton medium to fine counts | cotton / blends |

| JKS-AL* -034 | cloud | Bottom Apron | • high PU coated • general purpose quality • endless making with reactivator fluid | all fibres |

*ALE = Apron leather endless ALP = Apron leather open pre-glued